IMPORTENT FUNCTIONS :

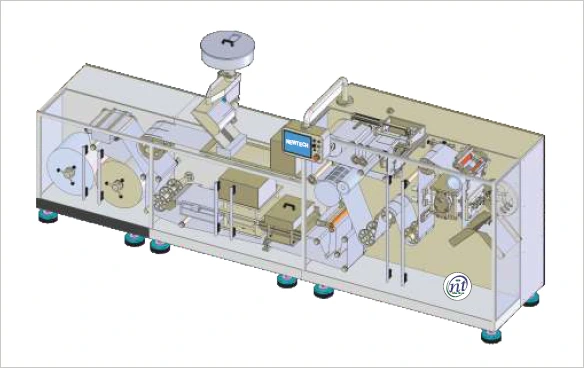

• The BLISTER PACKING MACHINE NT 300 is suitable for the production of blisters with various foils such as PVC, PVC / PVDC, PET, COC, ACLAIR, ALU / ALU material type for shaping blister holes. The offered machine does not have an alu / alu supply, as it is not currently required for the submitted packaging design

• The BLISTER PACKING MACHINE NT 300machine is suitable for packing tablets as well as capsules.

• The machine is having flat shape and a rotary seal

• When transporting the machine, Film is to be properly cleaned.

• The belt clamping system is designed in such a way to ensure that the belt is not inverted.

• The product feeder is designed based on the shape of the product and the current format in which it is designed is a gate gate feeder.

• Care is taken to avoid cross-contamination of the product feed.

• Transformation functions can be adapted to the smallest devices.

• The cut is cut off and collected in another box.

• The machine has a built-in print registration control system.

• The seal is rotary and creates the highest quality seal without leakage problems.

• Embossing and perforating stations available.

• The machine has four servomotors for indexing the product feeding belt, indexing the punching and punching, and selecting and storing blisters.

• Safety covers are elegantly made for easy operating support.

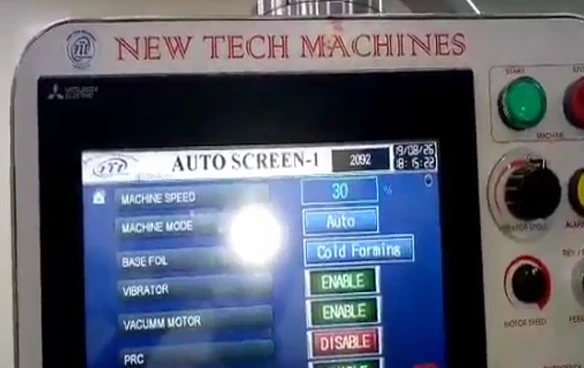

• The HMI has three levels of password control and can be assigned to individuals as needed.

• NFD option can be integrated as needed.

• The blister machine carries a rotating system for holding the blister and smooth delivery of the finished blister pack in cuneiform.

• The machine is equipped with a batch code printing unit.

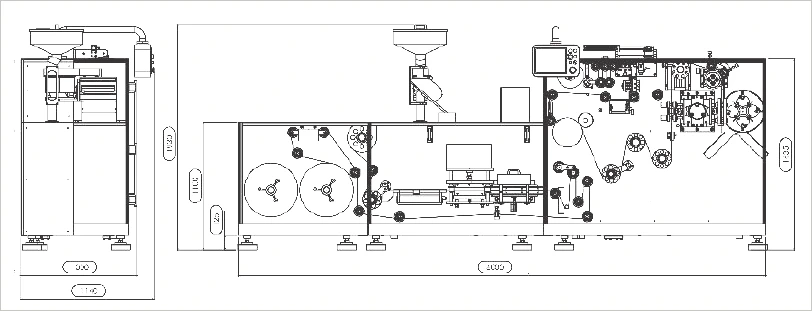

| TECHNICAL SPECIFICATIONS OF MODEL NT 300 MULTI PRODUCT | |

| MAX FOIL WIDTH | 300mm |

| MAX FORMING ADVANCE | 240mm |

| BASE FILM THICKNESS MAX | 0.25mm – 0.3 mm |

| LID FOIL THICKNESS MAX | 0.02 mm – 0.04 mm |

| FORMING AREA | 290 X 234 |

| SPEED | 40 Cycles/min ( COLD FORMING )

|

| 50 Cycles/min (THERMO FORMING) | |

| MAX FORMING DEPTH | 12mm |